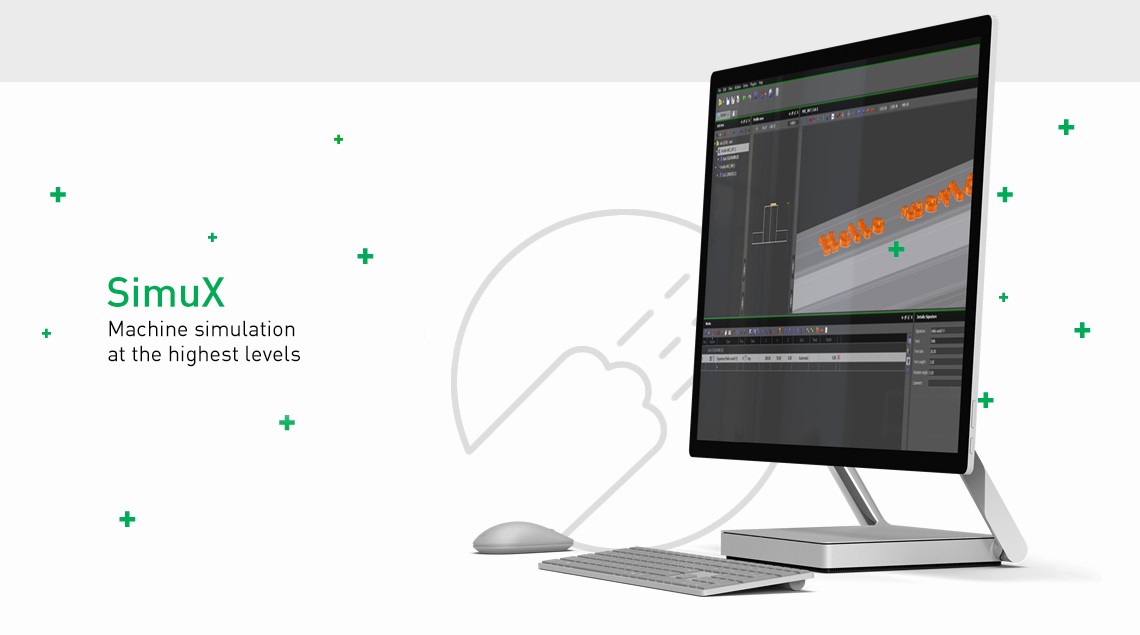

Start of new simulation application SimuX.

Brand-new year, brand-new application. In the difficult year 2020, we took a closer look at the machine simulation module of our PUMA system. As a result, we have developed the stand-alone application SimuX, which will be launched in 2021. Using the ISO CNC code of the respective control and a 3D model of the machine, SimuX simulates the NC program sequence of a machine. Thereby, the application is not only a simulation, but also a very powerful NC editor with a database-supported part program management.

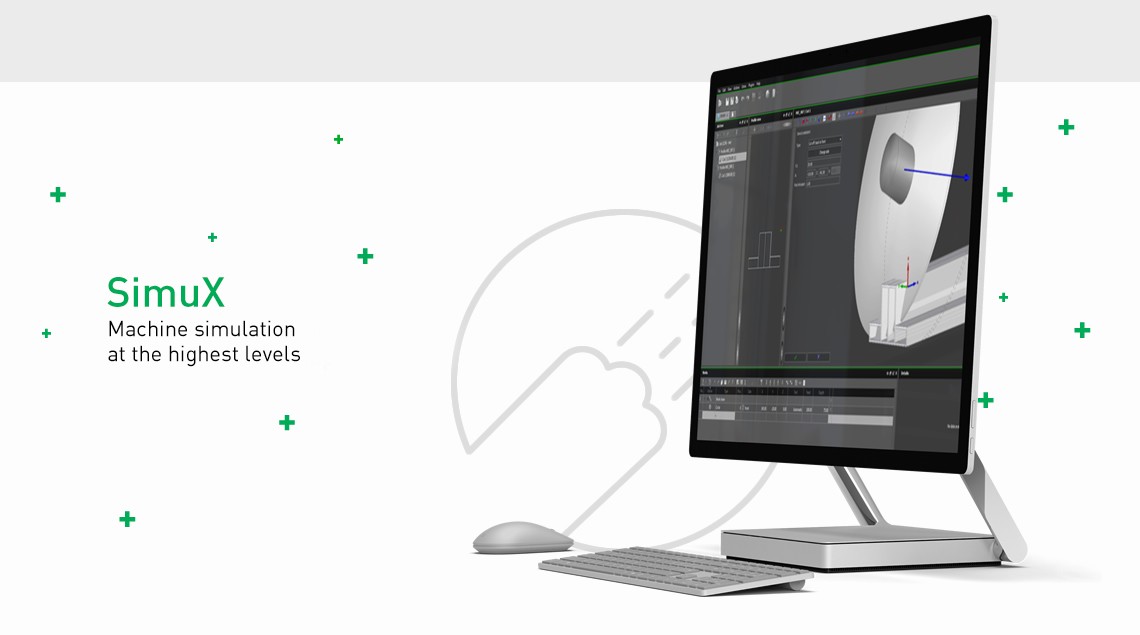

What does SimuX do?

In just a few words: material removal, collision control, end position control, time calculation of the CNC program. Calculation of the blank by material removal. True to detail even with 5-axis simultaneous machining. The collision control shows e.g. contact between spindle and clamping device or workpiece, collisions of the tool holder with the workpiece and even infeeds of the tool in rapid traverse, if the material of the workpiece has not yet been removed. The end position control checks the positions of all necessary machine axes.

During the time calculation of the CNC program, in addition to the total time, a listing of the program can be called up, in which each simulated NC line is listed with its own time. In doing so, the simulation does not have to be carried out in real time. The collision check, end position monitoring and time calculation are also performed correctly in accelerated mode. In addition, several control options are available for collision control and end position monitoring. You can choose whether end position violations should "only" be displayed or whether the simulation run should be interrupted in case of collisions. Using entry points for tool changes or clamp moving, the simulation can be entered without interrupting the entire program run. Critical situations can thus be analyzed in a systematic manner. With SimuX, programs can be checked before they are run on the machine. The operator can look at the sequence beforehand and take a closer look at critical situations. As the simulation is not a video, you can define the view and detail sections yourself. This application can support you in optimizing CNC programs for serial production. Retraction paths can be shortened, and unnecessary movements can be removed. The simulation allows you to check immediately whether the changes influence the program runtime. In other words, SimuX can help you reduce the run-in times, detect program and sequence errors beforehand and thereby avoid damaging the machine.

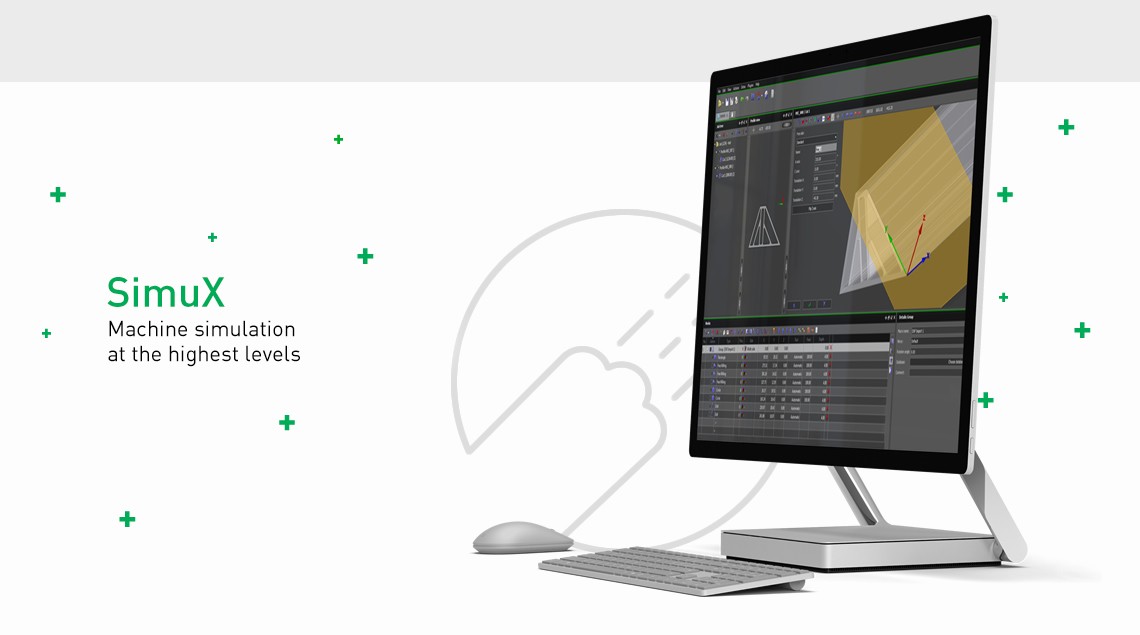

Where do the tools for SimuX come from?

The required tools are created in a seperate tool catalogue. Various options are available for the import. For example, you can directly import tool files from the CAM systems EluClad (*.NCT, EluSoft) and CAMPlus (tools.txt, Emmegi) or search the ISO code for freely definable keywords using a scan function. Existing tools can be edited by you or new tools can be created manually with a dialogue in the tool database.

What can the SimuX Editor do?

The SimuX editor lets you edit CNC programs very comfortably. Among other things, different colors can be freely defined for the components of the NC code. To enable you to move faster in the NC program, the navigator provides entry points In addition to the usual functions as search or find and replace, the SimuX Editor also has tools for sentence numbering.

Another plus of the SimuX editor is the record format specifications. This allows you to insert complex or recurring CNC text blocks, such as machining cycles, zero points, program start and program end, tool call, etc., into the program using input masks without syntax errors.

Which machines does SimuX know?

Basically, SimuX knows all machines and controls for which can be controlled by our PUMA system. These include the Elumatec SBZ151 and SBZ151 Edition 90, Emmegi Satellite XT, Handtmann / Bavius PBZ-NT with BWO or S840D, Maka AP70 and PA37. If you are interested, but your machine was not mentioned above, then send a short email to verwaltung@elusoft.com. We will be happy to create an individual SimuX machine simulation according to your specifications.

You are curious about SimuX and would learn more about the application?

Contact us at verwaltung@elusoft.com and we will get in touch with you as soon as possible