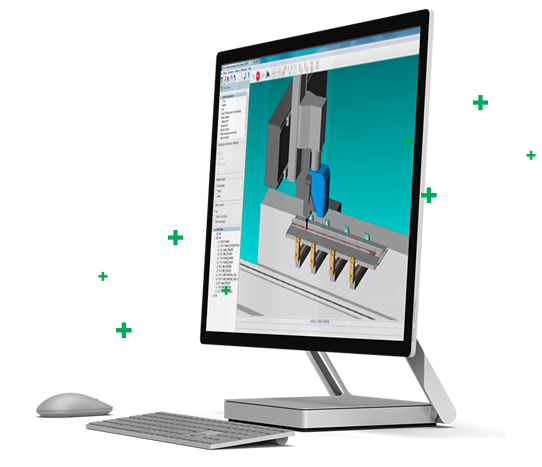

PUMA Pro

SOFTWARES / PUMA SystemThe perfect management of all the functions necessary for the milling of complex parts, such as the management of 5 interpolated axes, management of milling curved surfaces, management of curved parts and complete management of the touch probe module, together with the perfect management of the typical characteristics of the machining centers used for the machining of aluminum and light alloy bars, makes PUMA Pro the most suitable product for the management of 5-axis machining centers used in the aeronautics, rail transport and industrial sectors in general.

PROFILE PROCESSING

WITH MAXIMUM EFFICIENCY

- All common milling strategies

- Free Milling

- 5 axis simultaneous milling

- Surface milling

- Bended profiles management

- Innovative clamp management

- 3D simulation with machine model

- Creation of working papers

- Automatic feature recognition

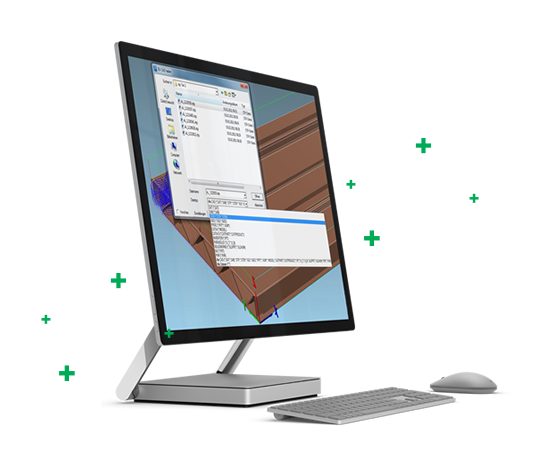

3D MODEL IMPORT

SUPPORTED FORMATS:

Default

SAT / SAB

Optional

STEP / IGES / PROE / CATIA / INVENTOR

PARASOLID / SOLIDWORK / NX / PAR

Automatic feature recognition (AFR)

Automatic recognition of machining operations

with a wide range of adjustment options.

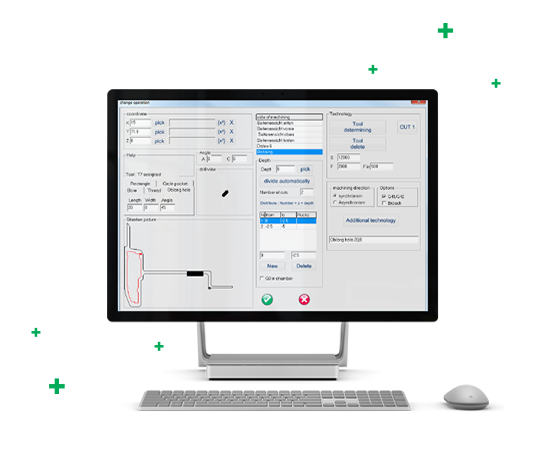

STANDARD OPERATIONS

Easy to create

> Drilling

> Threads

> Long holes

> Rectangle pockets

> Circle pockets (with/without Helix Interpolation)

Parameter

> Cut division

> Synchronous/Asynchronous

> Radius compensation

> Processing name

> Tool allocation

> G0 in profile chamber

SAWCUT

> Sawcuts from model surface

> Notching in all angles

> Determine angles per mouse-click

> Chop-cuts and cross-cuts

> 1-Click Notchingfunction

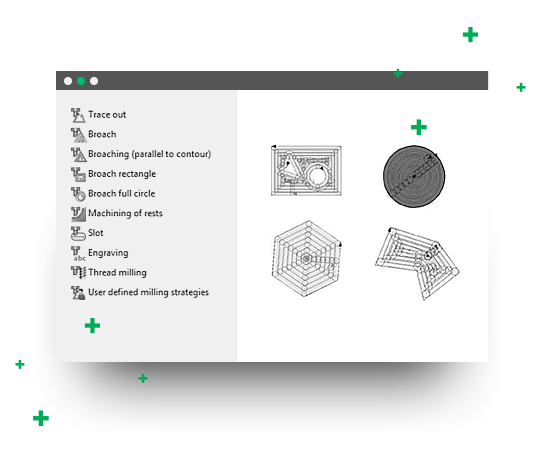

FREE MILLING

For any contours a wide range

of processing strategies are available.

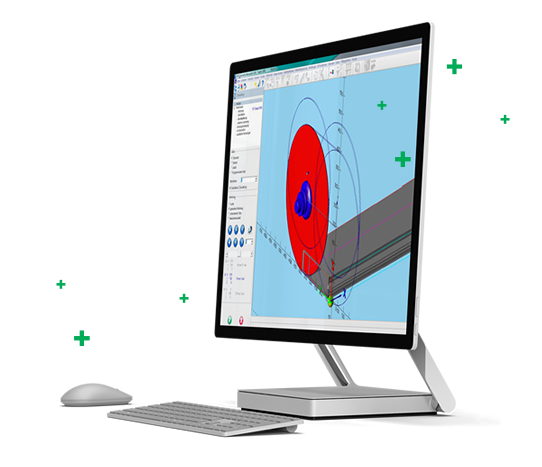

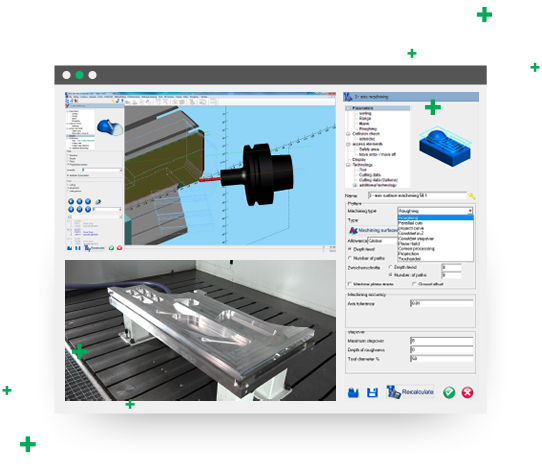

MODULEWORKS 3 AXIS

SURFACE MILLING MODULE

> All common milling strategies available

> Saving and loading parameter sets

> Collision test

> Test mode for the created path incl. tool display

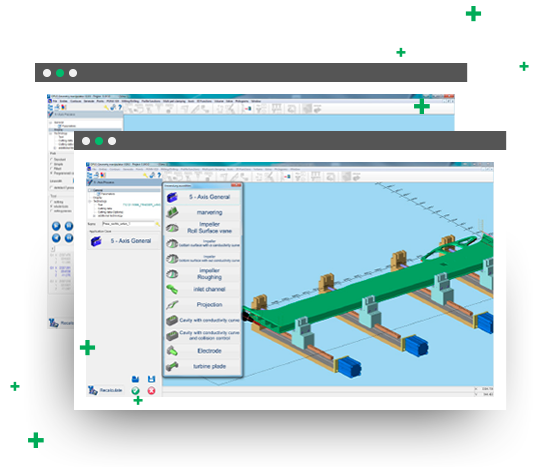

MODULEWORKS

5 AXIS MODULE

> Simple creation of the milling path

by edge/surface selection

> Test mode for the created path incl. tool display

> Preset for the most important machining methods

> Saving and loading parameter sets

RADIOPROBE: MEASURING

AND CORRECTION OF MACHINING

> Edge/surface measuring in all axis

> Set and assign measurement points

directly in the geometry

> Move the X - 0 point with measurement points

> Correction of contour elements

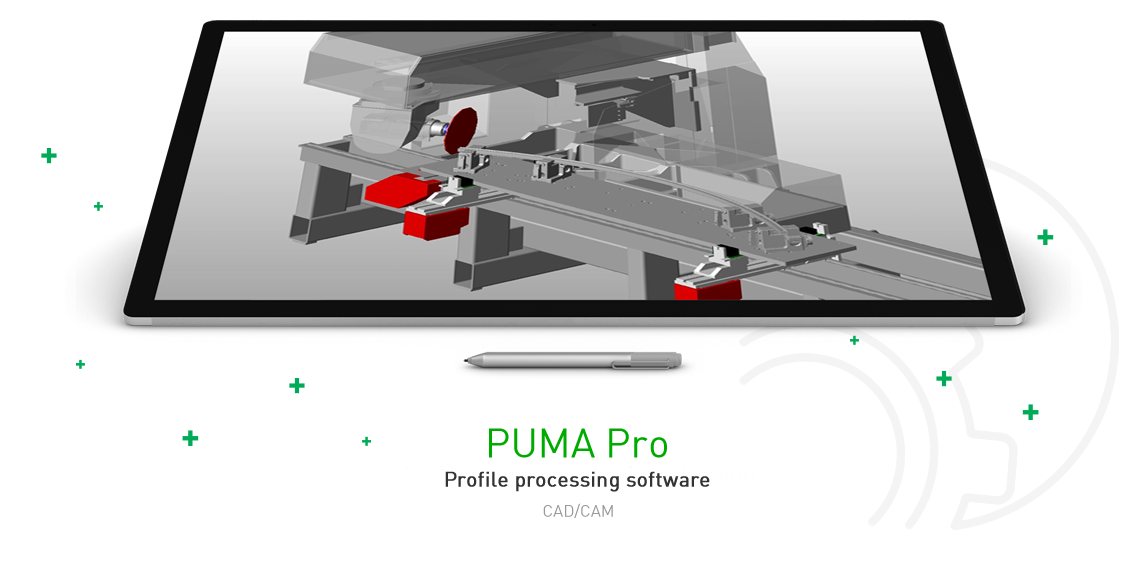

BENDED PROFILES MANAGEMENT

> Correct 3D view of curved profiles

> Real representation of clamps or equipment

> Real definition of approach and exit movements

> Representation of clamping devices

in the 3D simulation

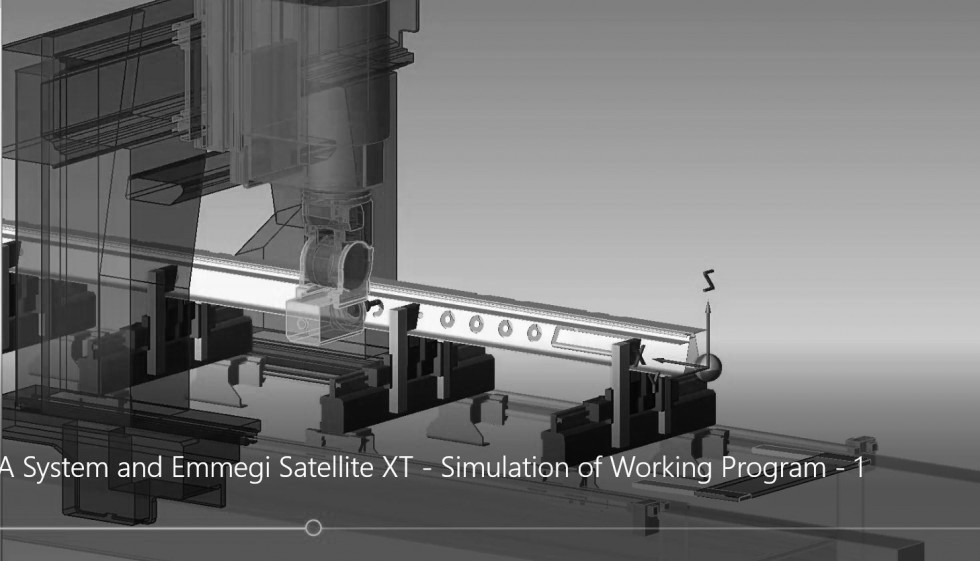

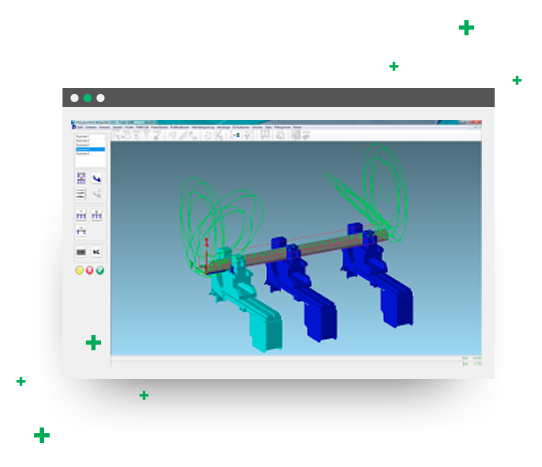

INNOVATIVE CLAMPING MANAGEMENT

> Movement of the clamps by mouse click

> Real representation of the clamps

> Fast sorting of the processing order

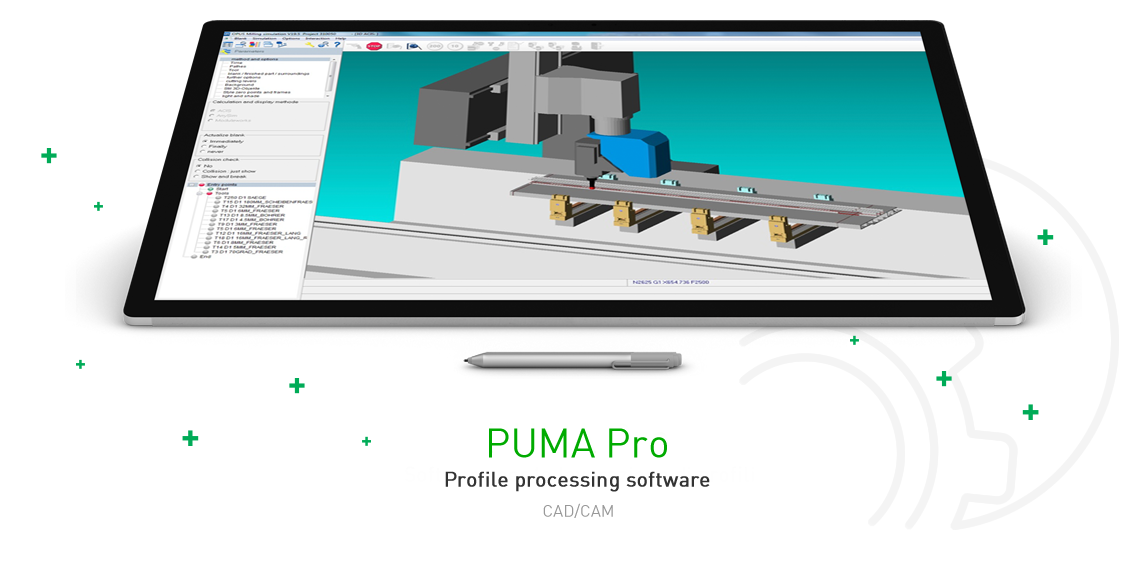

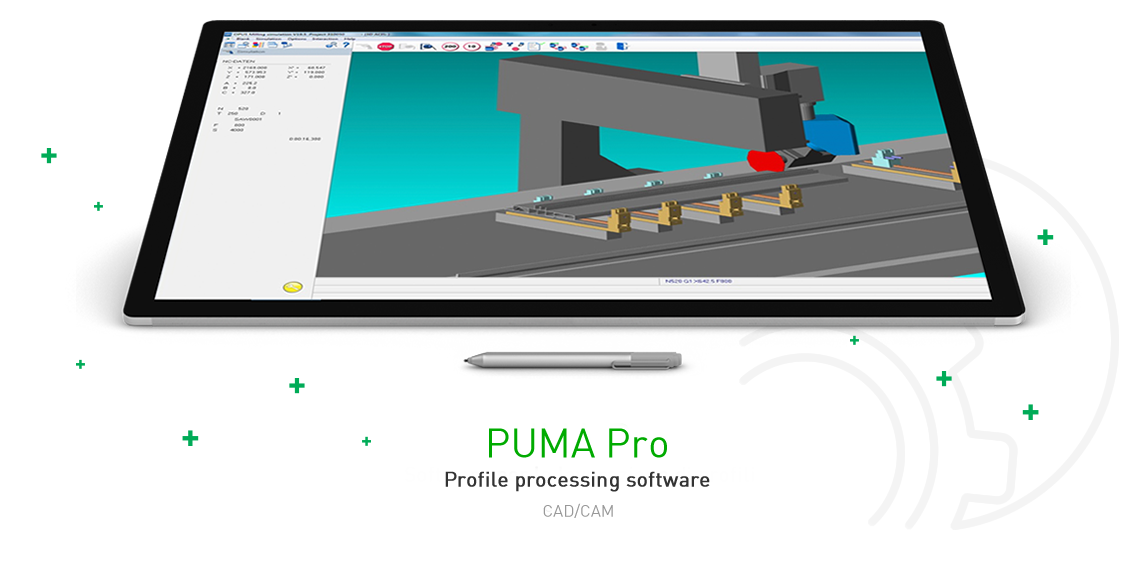

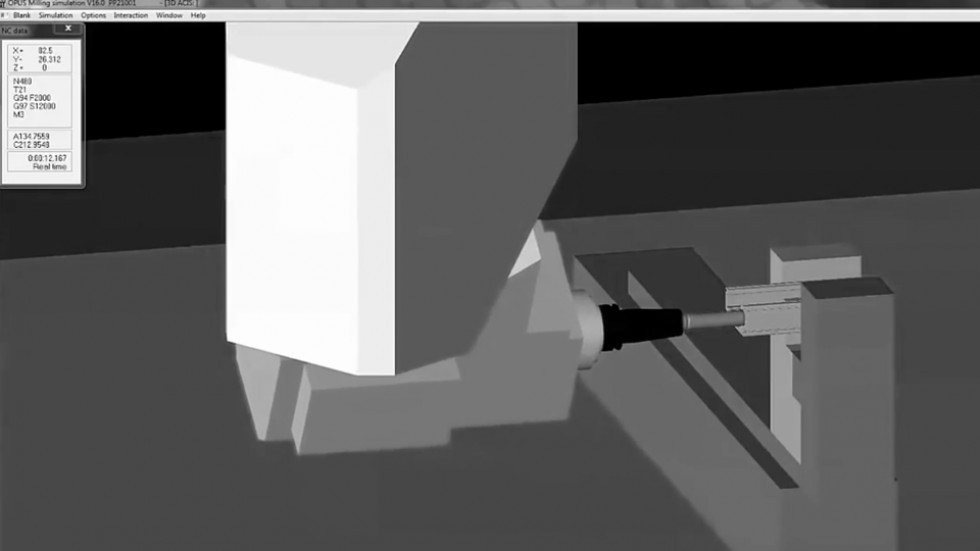

3D SIMULATION

> Simulation directly from the NC code

> Visible removal of material

> Start from any tool

> Display of the axis positions

> Display of current tools

> Display of the cutting data

> Display of the processing time